G80 Jig Overview

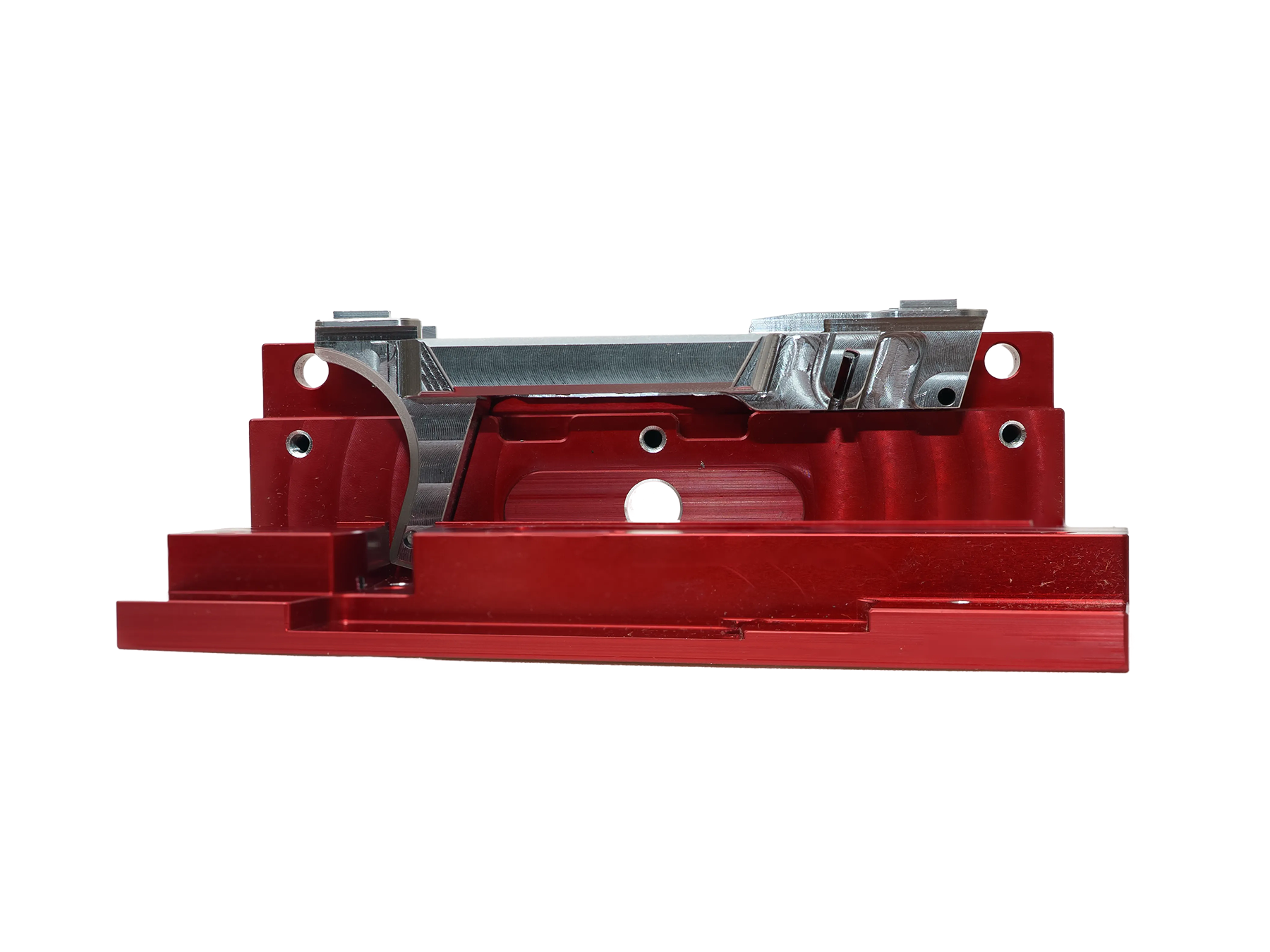

The G80 Jig is a precision finishing tool engineered specifically for the G80 Unfinished Receiver. No modifications, no adapters, no compatibility guesswork. Drop in your receiver, secure the jig, and start working. This is the only jig designed for the G80 platform, and it shows in the fit.

The G80 Jig supports both manual and machine finishing. Use a Dremel with the included grinding stones and drill bits, or mount it in a Ghost Gunner GG3-S for automated milling. Either way, the precision-machined aluminum construction eliminates the walk, chatter, and misalignment that plague universal jigs. Clean cuts, proper pin alignment, professional results.

Unlike disposable jigs bundled with cheaper 80% kits, the G80 Jig is built for repeated use. The tolerances hold build after build, making it the right choice if you’re finishing multiple receivers or helping others complete their builds. Made in USA. Current lead time is 6 weeks. Price: $219.99.

What’s Included with the G80 Jig

1x G80 Jig Hardware Set

2x 3.1mm Drill Bits

1x 4.1mm Drill Bit

1x Grinding Stone (Large)

The included drill bits are specifically sized for the G80’s pin holes. No hunting down third-party bits or adapters. Everything you need to finish your receiver comes in the box.

What Makes the G80 Jig Different

Purpose-Built for G80

The G80 Jig is engineered exclusively for the G80 Unfinished Receiver. Not a universal jig with adapters. Not a polymer frame jig repurposed for steel. The receiver drops in with zero modifications, and the pin hole guides align perfectly with the G80’s specifications. This eliminates the fit issues that cause failed builds with generic jigs.

Manual or Machine Ready

The G80 Jig works with your preferred finishing method. For manual builds, use a Dremel rotary tool with the included grinding stone (recommended cutters: SKU 85602 and 85422). For automated finishing, the jig mounts directly in the Ghost Gunner GG3-S. You can also use a drill press with a 1/4″ end mill for peck-drilling. Same jig, multiple workflows.

Precision-Machined Aluminum

The G80 Jig is CNC-machined from aluminum to tight tolerances. This isn’t injection-molded plastic that flexes under pressure. The rigid construction prevents walk and chatter during milling, and the precision guides ensure your pin holes end up exactly where they need to be. Your finished receiver will have proper alignment for reliable function.

Built for Repeated Use

Disposable jigs lose accuracy after one build. The G80 Jig maintains its tolerances across multiple receivers. If you’re building for yourself, helping friends finish their G80s, or just want tooling that lasts, this jig pays for itself. It’s an investment in your workshop, not a consumable.

VanDerStok Compliance Built In

The G80 system was designed to meet the Supreme Court’s VanDerStok standard, which requires over an hour to complete. Manual finishing with the G80 Jig typically takes 1-2 hours for first-time builders, maintaining compliance while delivering a quality result.

G80 Jig FAQ

What tools do I need to use the G80 Jig?

Is the G80 Jig reusable?

How long does it take to finish a G80 receiver with the G80 Jig?

Will the G80 Jig work with Polymer80 or other 80% frames?

What’s included with the G80 Jig?

Can I use a drill press instead of a Dremel with the G80 Jig?

Why does the G80 Jig cost more than jigs included with other 80% kits?

What Glock parts work with a completed G80?

Specifications

Material: CNC-Machined Aluminum

Weight: 48 oz

Dimensions: 10 × 6 × 4 in

Options: Manual (Dremel), Machine (Ghost Gunner GG3-S)

Included: Jig hardware set, 2x 3.1mm drill bits, 1x 4.1mm drill bit, large grinding stone

Compatible With: G80 Unfinished Receiver only

Not Compatible: Polymer80, GST-9, or any other 80% platform

Reusable: Yes, maintains tolerances across multiple builds

Disclaimer

This product is not manufactured, authorized, endorsed, or warranted by GLOCK. GLOCK does not warrant or represent that this product is compatible with GLOCK pistols.

“GLOCK” is a federally registered trademark of GLOCK, Inc. and is one of many trademarks registered by GLOCK, Inc. and GLOCK Ges.m.b.H. Neither Ghost Guns, nor this site are affiliated in any manner with, or otherwise endorsed by, GLOCK, Inc. or GLOCK Ges.m.b.H. The use of “GLOCK” on this page is merely to advertise the sale of products compatible with GLOCK pistols, parts, or components. For genuine GLOCK, Inc. and GLOCK Ges.m.b.H products and parts visit www.glock.com.

![AR15 Raw Lower Receiver [80%]](https://ghostgunsdotcom.s3.us-east-2.amazonaws.com/wp-content/uploads/2025/06/80-percent-ar15-raw.png)